GDCO-301 Online Monitoring System of Circulating Current on Cable Sheath

Cables above 35kV are mainly single-core cables with metal sheath. Since the metal sheath of the single-core cable is hinged with the magnetic field line generated by the AC current in the core wire, the two ends of the single-core cable have a high induced voltage. Therefore, appropriate grounding measures should be taken to keep the induced voltage within the safe voltage range (usually no more than 50V, but no more than 100V with safety measures). Usually, the metal sheath of short line single-core cable is grounded directly at one end and grounded through gap or protection resistor at the other end. The metal sheath of long line single - core cable is grounded by three - phase segmental cross - connection. No matter which kind of grounding method is adopted, good sheath insulation is necessary. When the insulation of the cable is damaged, the metal sheath will be grounded at multiple points, which will generate the circulating current, increase the loss of the sheath, affect the current carrying capacity of the cable, and even cause the cable to be burned due to overheat. At the same time, guarantee the high voltage cable metal sheath grounding directly connect site is also very important, if the ground point cannot effectively be grounded for various reasons, the cable metal sheath potential will rise sharply to several kilovolts even tens of thousands of volts, it is easy to lead to outer sheath breakdown and continuous discharge, causing the rise of the temperature of cable outer sheath or even burning.

GDCO-301 uses the circulating current method. When the single-core cable metal sheath is under normal conditions (i.e., one-point grounding), circulating current on the sheath, mainly capacitive current, is very small. Once multi-point earthing occurs on the metal sheath and forms a loop, circulating current will increase significantly and can reach more than 90% of the main current. Real-time monitoring of metal sheath circulation and its changes can realize on-line monitoring of multi-point earth fault of single-core cable metal sheath, so as to timely and accurately find the earth fault, fundamentally avoid the occurrence of cable accident and ensure the safe and reliable operation.

It uses GSM or RS485 as communication mode. It is suitable for multi-point ground fault monitoring of single core cables above 35kV.

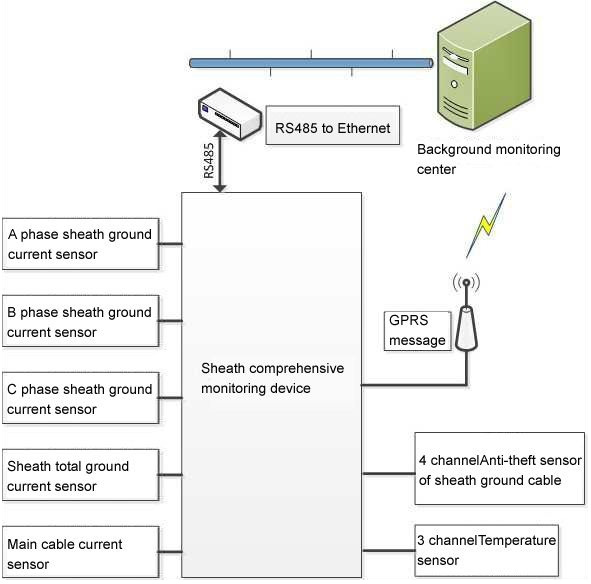

GDCO-301 Online Monitoring System of Circulating Current on Cable Sheath includes: main unit of integrated monitoring device and current transformer, temperature and anti-theft sensor. The open type current transformer is installed on the ground line of the cable sheath and is converted into a secondary signal before the monitoring device is introduced. The temperature sensor is used to monitor the cable temperature, and the anti-theft sensor is used to monitor the circulation grounding line. The composition of comprehensive online monitoring system of cable sheath is as follows:

● Real-time monitoring of the ground current of three phase cable sheath, the total ground current and the operating current of any phase main cable;

● Real-time monitoring of three-phase cable temperature;

● Real-time anti - theft monitoring of cable sheath grounding;

● Time interval can be set;

● Alarm parameters and whether corresponding monitoring parameters are allowed to generate alarm can be set;

● Set the maximum value, minimum value and average value in the preset period;

● Real-time monitoring of the ratio of maximum and minimum value of single-phase ground current within the statistical period, and alarm?processing;

● Real-time monitoring of the ratio of ground current to load within the statistical period, and alarm processing;

● Real-time monitoring of the change rate of single-phase ground current within the statistical period, and alarm processing;

● The measurement data can be sent at any time.

● Can specify one or more monitoring parameters to alarm, send alarm information to the designated mobile phone;

● Real-time measurement of input voltage;

● All monitoring data have time labels to ensure the uniqueness of the data;

● All monitoring sensors can be configured according to user requirements;

● Multiple data transmission interfaces: RS485 interface, GPRS, GSM SMS, can use one or more data transmission modes at the same time;

● Support remote maintenance and upgrade;

● Low power consumption design, support a variety of power input: CT induction power, AC-DC power and battery power;

● With industrial grade components, with good reliability & stability;

● Modular fully enclosed structure, easy to install, locking measures are taken on all parts, good anti-vibration performance, and easy to replace and disassemble;

● Support IP68 protection level.

|

Item |

Parameters |

|

|

? ? Current ? |

Operating current |

1?channel,?0.5~1000A?(Can be customized) |

|

Sheath ground current |

4?channel,?0.5~200A?(Can be customized) |

|

|

Measurement accuracy |

±(1%+0.2A) |

|

|

Measurement period |

5~200s |

|

|

? Temperature |

Range |

-20℃~+180℃ |

|

Accuracy |

±1℃ |

|

|

Measurement period |

10~200s |

|

RS485 port

● Baud rate: 2400bps, 9600bps and 19200bps can be set.

● Data length: 8 bit:

● Start bit: 1 bit;

● Stop bit: 1 bit;

● Calibration: no calibration;

GSM/GPRS port

● Working frequency: Quad-band, 850 MHz/900 MHz/1800 MHz/1900 MHz;

● GSM Chinese/English short mesages;

● GPRS class 10, Max. download speed 85.6 kbit/s, Max. upload speed 42.8 kbit/s, support TCP/IP, FTP and HTTP protocol.

Power supply

AC power supply

● Voltage: 85~264VAC;

● Frequency: 47~63Hz;

● Power: ≤8W

Battery

● Voltage: 6VDC

● Capacity: determined by continuous working time of battery

● Battery compatibility

|

Electrostatic discharge immunity |

Class?4:?GB/T 17626.2 |

|

Radio-frequency electro-magnetic field radiation immunity |

Class?3:?GB/T 17626.3 |

|

Electric fast transient/burst immunity |

Class?4:?GB/T 17626.4 |

|

Surge immunity |

Class?4:?GB/T 17626.5 |

|

Radio-frequency field inductive conduction immunity |

Class?3:?GB/T 17626.6 |

|

Power frequency magnetic field immunity |

Class?5:?GB/T 17626.8 |

|

Pulse magnetic field immunity |

Class?5:?GB/T 17626.9 |

|

Damping oscillation magnetic field immunity |

Class?5:?GB/T 17626.10 |

Reference standard:

Q/GDW 11223-2014: Technical Specification for state detection for high voltage cable lines

4.1 Cable state detection can be divided into two categories: online detection and offline detection. The former includes infrared detection, ground current detection of cable sheath, partial discharge detection, while the offline detection contains partial discharge detection under variable frequency series resonant test, oscillation cable partial discharge detection.

4.2 Cable state detection modes include general test on a large scale, retest on suspected signals, test focused on faulty equipment. In this way, cable normal operation can be guaranteed.

4.3 Detection staff should attend technical training of cable detection and hold certain certificates.

4.4 Basic requirement of terminal infrared imager and ground current detector refer to Appendix A. Basic requirement of high voltage partial discharge detection, ultra high voltage partial discharge detection and ultrasonic partial discharge detector refer to Q/GDW11224-2014.

4.5 Range of application refers to Table 1.

| Method | Voltage grade of cable | Key detection point | Defect | Online/offline | Remarks |

| Thermal infrared image | 35kV and above | Terminal, connector | Poor connection, damped, insulation flaw | Online | Compulsory |

| Metal sheath ground current | 110kV and above | Grounding system | Insulation flaw | Online | Compulsory |

| High frequency partial discharge | 110kV and above | Terminal, connector | Insulation flaw | Online | Compulsory |

| Ultra high frequency partial discharge | 110kV and above | Terminal, connector | Insulation flaw | Online | Optional |

| Ultrasonic wave | 110kV and above | Terminal, connector | Insulation flaw | Online | Optional |

| Partial discharge under variable frequency series resonant test | 110kV and above | Terminal, connector | Insulation flaw | Offline | Compulsory |

| OWTS oscillation cable partial discharge | 35kV | Terminal, connector | Insulation flaw | Offline | Compulsory |

Table 1

| Voltage grade | Period | Remarks |

| 110(66)kV | 1. Within 1 month after operation or major repair 2. Once for other 3 months 3. If required |

1. Detection period should be shortened when there is heavy load on cable lines or during summer peak. 2. Detection should be done more frequently based on bad work environment, outdated equipment, and defective device. 3. Proper adjustments should be made based on equipment's conditions and work environment. 4. Online monitoring system of ground current on cable sheath can replace its live detection. |

| 220kV | 1. Within 1 month after operation or major repair 2. Once for other 3 months 3. If required |

|

| 500kV | 1. Within 1 month after operation or major repair 2. Once for other 3 months 3. If required |

Table 4

5.2.3 Diagnostic criteria

It is necessary to combine load of cable and abnormal current trend of cable sheath with measurement data of cable sheath.

Diagnostic criteria refers to Table 5.

| Test | Result | Advice |

| If all requirements below are met: 1. Absolute value of ground current<50A; 2. The ratio between ground current and load<20%; 3. Max. value/ Min. value of single phase ground current?<3 |

Normal | Operate as normal |

| If any requirement below is met: 1. 50A≤absolute value of ground current ≤100A; 2. 20%≤the ratio between ground current and load ≤50%; 3. 3≤Max. value/Min. value of single phase ground current≤5; |

Caution | Strengthen monitoring and shorten detection period |

| If any requirement below is met: 1. Absolute value of ground current>100A; 2. The ratio of ground current and load?>50%; 3. Max. value/Min. value of single phase ground current>5 |

Defect | Power off and check. |

Table 5